When it comes to maximizing efficiency and performance, the fuel quality is a crucial factor. Diesel fuel, over time, can become contaminated by impurities like water or sediment. This can cause engine malfunctions and require costly repairs. Polishing the fuel is an excellent way to ensure that engines run without a hitch and to combat contamination of fuel.

Polishing of fuel is also known as polishing of diesel fuel. It involves the elimination of impurities and contaminants from diesel fuel. It is a highly-specialized service that is provided by experts who use modern techniques and equipment to return fuel to its best condition. Polishing fuel can improve the performance of engines as well as reduces the cost of maintenance and prolongs the lifespan of equipment by removing harmful substances, and improving the quality of fuel.

A variety of polishing and cleaning services are offered to meet the varied requirements of various industries that rely on diesel fuel. These services are provided by highly trained technicians with experience in fuel systems who comprehend the complexity of contaminating fuel. Their extensive knowledge and special tools enable them to identify fuel-related problems and apply the proper methods of polishing your fuel.

The primary objective of polishing fuel is to remove water, sediment, sludge, and microbial contaminants from diesel fuel. The accumulation of water in fuel tanks could be triggered through leaks or condensation that can cause corrosion, fuel degradation and the growth and spread of mold and bacteria. Sludge and sediment, in contrast, can result from impurities within the fuel or result from the degrading of components of the fuel over time. These pollutants can clog the injectors and filters as as other essential components. This could result in lower engine performance or even breakdown.

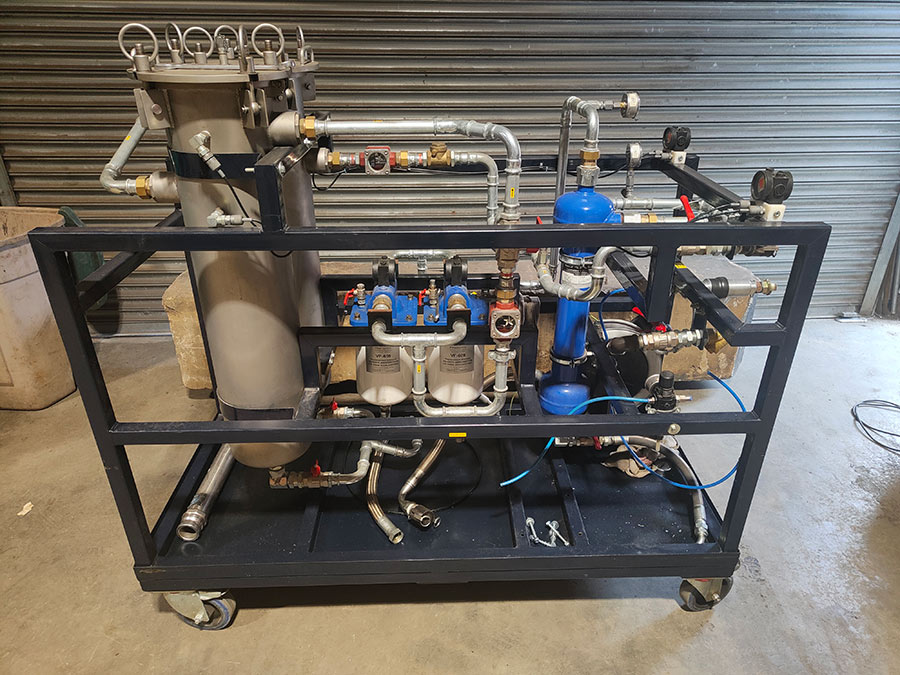

Diesel fuel polishing typically involves a multi-step process. Analysis and sampling of fuel is the initial step to find out the degree of contamination. When the analysis is complete technicians utilize filtration systems to remove impurities and contaminants from the fuel. The systems employ various filtering media and techniques to separate and capture contaminants and leave pure diesel.

Regular fuel polishing offers several key benefits. It improves the quality of the fuel and ensures that engines get regular, clean fuel for optimal combustion. Fuel efficiency and performance are enhanced, which results in less emissions and lower costs. Additionally, polishing the fuel reduces the risk of engine damage and breakdowns caused by fuel that is contaminated. It assists in maintaining the integrity and longevity of engine parts by eliminating harmful substances.

Polishing diesel is a common procedure that can provide many benefits to keep the fuel quality. It assists in removing water particles, sediments and microbial contaminants which could impact the performance of engines. The quality of the fuel is improved significantly through the removal of these impurities by the polishing process for diesel. The improved combustion efficiency leads to increased fuel economy and lower emissions. Additionally, regular polishing of diesel stops the blockage of fuel filters, injectors, and other crucial components, reducing the possibility of engine damage and costly repairs. Regularly cleaning the fuel system also ensures that storage systems for fuel last longer, by preventing the buildup of corrosion and sludge. Polishing diesel or regularly scheduled fuel cleaning can improve engine performance and decrease cost. Additionally, it improves equipment reliability.

Fuel polishing can also be adjusted to meet the specific requirements of different industries and application. From backup generators and vessels for marine use to construction equipment as well as transport fleets, fuel polishing is a variety of solutions to deal with pollution of the fuel supply across a vast spectrum of sectors. The process of polishing fuel is crucial for industries that depend on an constant and reliable power supply. It’s also important for those working in harsh, remote areas, where fuel quality can be compromised.

In summary, fuel polishing is a vital process that helps ensure the purity and high-quality of diesel fuel. It boosts engine performance decreases maintenance costs and extends the lifespan of equipment by eliminating pollutants and impurities. By investing in professional polishing techniques, businesses are able to protect their operations, enhance performance and reduce the risk associated with fuel contamination. The process of polishing fuel is a potent tool that can be used to boost the performance of your diesel fuel.